Deep learning for quality controls of mechanical components

One of the many aspects where deep learning is revolutionizing the industry is that of quality control and fault detection.

This blog post describes the result of a collaboration between flair-tech and Qvision for the quality control of mechanical components. The problem is to check whether a spherical mechanical part, is correctly glued to a surface.

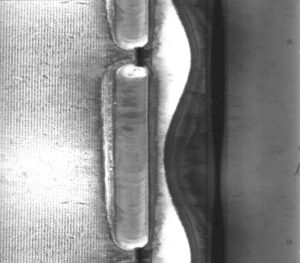

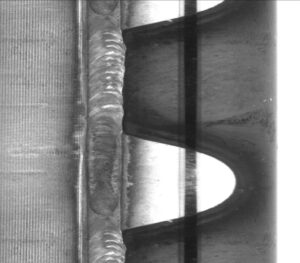

This can be done by visual inspection. We can see an example here below. The picture is taken with a camera from above when the sphere is rolling. You can imagine slicing the sphere and taking a picture of its flattened self.

Example of a photo of a spherical mechanical component.

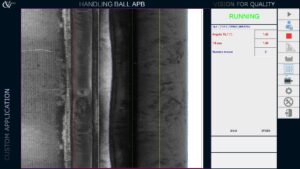

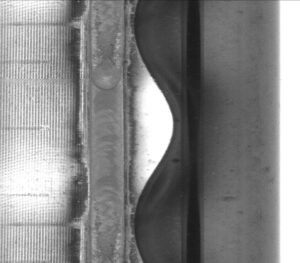

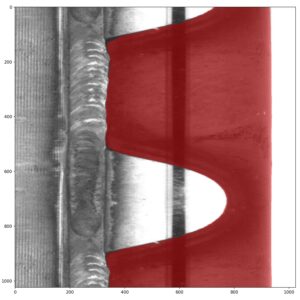

Simple calculations (tilt angle and such) can be performed to determine if the components are not properly glued if we can correctly identify the area of the sphere in the picture, in particular its border. We can see an example here below.

Fault detection system using tilt angle once the border of the sphere is identified.

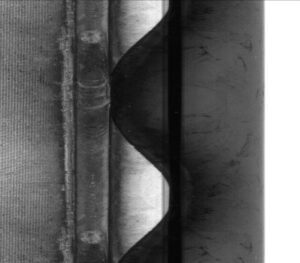

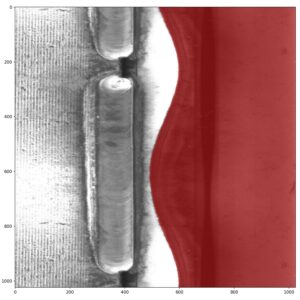

However, identifying such an area in the pictures is not a trivial task if approached with traditional vision techniques like filters, edge detectors, morphological operators, and such. This is due to the significant various nature of the pictures as shown down below.

Deep learning can greatly help in this situation as it is designed to learn general concepts and adapt to changing scenarios.

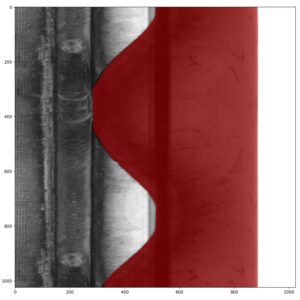

In particular, for this task, we adopted a neural network for semantic segmentation. That is a network that takes an input image and produces a segmentation (at pixel level) of the image according to different semantic areas. To be able to do this we have to train the network by providing some examples of how we would like the network to segment an image.

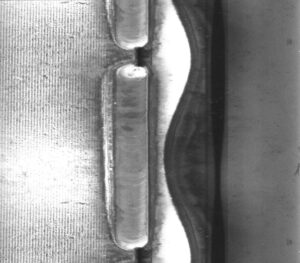

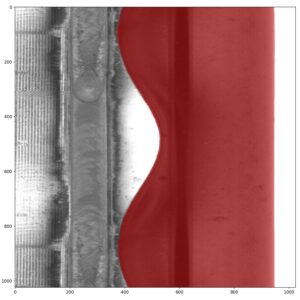

Here are the results!

Stay tuned to flair-tech.com for more blog posts about our active projects.